|

|

, ,

Inconel &

& |

|

,

,

,

|

|

Specializing in ON TIME delivery

of Super Duplex, Duplex, Titanium, 254SMO and Nickel Alloys

When you need an alloy now, call Alloys Now.  863-607-6119 863-607-6119

sales@alloys-now.com sales@alloys-now.com

3607 Ventura Dr. East, Lakeland, FL 33811,

USA, Fax: 863-607-6602 |

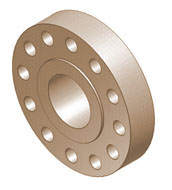

Flanges

Flanges in Duplex - UNS S31803 & S32205

Flanges in Super Duplex - UNS S32750 & S32760

Flanges in 6 Moly - UNS S31254, N08925 &

N08926 |

|

Types |

|

Slip-on |

Socket Weld |

Weld Neck |

Spectacle Blind |

Orifice |

|

Threaded |

Reducing |

Lap Joint |

Blind |

|

|

Materials |

Grades |

Sizes |

Designations |

Pressures |

|

Titanium |

TI Grade 2 UNS R50400

Ti Grade 7 UNS R52400 |

1/2" - 24" |

Sch 10S > Sch 160 |

150lbs > 600lbs |

Duplex SS

Ferritic Austenitic |

UNS S31803

UNS S32205 |

1/2" - 60" |

Sch 10S > Sch XXS |

150lbs > 2500lbs

API 6BX 5K, 10K, 15K |

Super Duplex SS

Ferritic Austenitic |

UNS S32750

UNS S32760

UNS S32550 |

1/2" - 36" |

Sch 10S > Sch XXS |

150lbs > 2500lbs

API 6BX 5K, 10K, 15K |

6% Molydenum SS

Super Austenitic |

UNS S31254

UNS N08926

UNS N08867 |

1/2" - 36" |

Sch 10S - Sch XXS |

150lbs > 2500lbs

API 6BX 5K, 10K, 15K |

|

SS 317L |

UNS S31703 |

1/2" - 60" |

Sch 10S - Sch XXS |

150lbs > 2500lbs

API 6BX 5K, 10K, 15K |

|

Alloy 625 (Inconcel®) |

UNS N06625 |

1/2" - 36" |

Sch 10S - Sch XXS |

150lbs > 2500lbs

API 6BX 5K, 10K, 15K |

|

Alloy C276 (Hastelloy®) |

UNS N10276 |

1/2" - 36" |

Sch 10S - Sch XXS |

150lbs > 2500lbs

API 6BX 5K, 10K, 15K |

|

Alloy 400 (Monel®) |

UNS N04400 |

1/2" - 36" |

Sch 10S - Sch XXS |

150lbs > 2500lbs

API 6BX 5K, 10K, 15K |

|

Alloy 20 |

UNS N08020 |

1/2" - 36" |

Sch 10S - Sch XXS |

150lbs > 2500lbs

API 6BX 5K, 10K, 15K |

|

SS 304h |

UNS S30409 |

1/2" - 60" |

Sch 10S - Sch XXS |

150lbs > 2500lbs

API 6BX 5K, 10K, 15K |

|

SS 321H |

UNS S32109 |

1/2" - 60" |

Sch 10S - Sch XXS |

150lbs > 2500lbs

API 6BX 5K, 10K, 15K |

|

SS 347H |

UNS S34709 |

1/2" - 60" |

Sch 10S - Sch XXS |

150lbs > 2500lbs

API 6BX 5K, 10K, 15K |

|

Maximum Allowable non-shock Pressure (psig) |

Temperature

(oF) |

Pressure Class (lb.) |

|

150 |

300 |

400 |

600 |

900 |

1500 |

2500 |

|

Hydrostatic Test Pressure (psig) |

|

450 |

1125 |

1500 |

2225 |

3350 |

5575 |

9275 |

|

-20 to 100 |

285 |

740 |

990 |

1480 |

2220 |

3705 |

6170 |

|

200 |

260 |

675 |

900 |

1350 |

2025 |

3375 |

5625 |

|

300 |

230 |

655 |

875 |

1315 |

1970 |

3280 |

5470 |

|

400 |

200 |

635 |

845 |

1270 |

1900 |

3170 |

5280 |

|

500 |

170 |

600 |

800 |

1200 |

1795 |

2995 |

4990 |

|

600 |

140 |

550 |

730 |

1095 |

1640 |

2735 |

4560 |

|

650 |

125 |

535 |

715 |

1075 |

1610 |

2685 |

4475 |

|

700 |

110 |

535 |

710 |

1065 |

1600 |

2665 |

4440 |

|

750 |

95 |

505 |

670 |

1010 |

1510 |

2520 |

4200 |

|

800 |

80 |

410 |

550 |

825 |

1235 |

2060 |

3430 |

|

850 |

65 |

270 |

355 |

535 |

805 |

1340 |

2230 |

|

900 |

50 |

170 |

230 |

345 |

515 |

860 |

1430 |

|

950 |

35 |

105 |

140 |

205 |

310 |

515 |

860 |

|

1000 |

20 |

50 |

70 |

105 |

155 |

260 |

430 |

|

|

Slip-On Flanges

Slipped over pipe and then welded both inside

and outside to provide sufficient strength and prevent leakage.

Used in preference to weld necks due to lower cost and less accurate

requirements when cutting the pipe to length. |

|

|

|

Blind Flanges

Without a bore, the blind flange is used to shut

off a piping system or vessel opening. Permits easy access for

inspection purposes. Can be supplied with or without hubs at

the manufacturers option. |

|

|

|

Weld-Neck Flanges

Designed to be joined to a piping system with

butt welding. Although relatively expensive due to long neck,

preferred for high stress applications. The bore of the flange

matches the bore of the pipe, reducing turbulence and erosion. |

|

|

|

Threaded Flanges

Similar to slip-on but bore is threaded enabling

assembly without welding which obviously limits use to relatively

low pressure systems. May be welded along joint after assembly,

but not considered satisfactory method of increasing applications. |

|

|

|

Socket Weld Flanges

Similar to slip-on in outline but bore is counter-bored

to accept pipe with the diameter of the remaining bore the same

as the inside diameter of the pipe. Attached to the pipe by a

fillet weld around the hub and an optional interval weld can

be applied in high stress applications. Often used in high pressure

systems such as hydraulics & steam lines. |

|

|

|

Lap-Joint Flanges

Similar to slip-on flange, but has a radius at

the intersection of the bore and the flange face to accommodate

a lap stub end. Face on stub end forms the gasket face of the

flange. Used when sections of piping needs to be dismantled quickly

and easily for inspection or replacement. |

|

|

|

Orifice Flanges

Provides access for metering off gases or liquids.

Clamps between a pair of flanges when installed in line and is

referred to as an orifice flange union. Jack-screws facilitate

removal of orifice plate. |

|

|

|

Spectacle Blank

Also called a Figure 8 Blank, the Spectacle Blank

is a pressure retaining plate with one solid end and one open

end connected with a web or tie-bar. Open end forms seal between

two flanges for normal flow of fluid through pipe work, and swinging

solid end into position halts flow. |

|

|

|

|

|

|

|